Sheet Metal Operations

MEASURING AND MARKING:

LAYING OUT:

For completing the above work the shape of the object should be carefully checked and it should be divided into simple geometrical solids. Then the solid obtained by above division can be developed separately and then sheet is cut. These separate pieces are joined together. It will give the required object.

Basic concept of development of surfaces is explained as, let us take a cylinder which is wrapped round its curved surface by a piece of paper. If wrapper is opened and spread on the sheet it forms a rectangle. The surface is the development of complete circular surface.

CUTTING AND SHEARING:

The word cutting is normally used when the sheet metal is cut by means of chisel and a hammer manually. The term shearing stands for cutting of sheet metal by two parallel cutting edges moving in opposite direction. This can be done either manually by using head shear or snips or by means of machines called shears. The operation is then known as machine shearing or mechanical shearing.

HAND FORMING:

The term metal forming stands for shaping or bending of sheet metal in three dimensions in order to give it desired shape and size of the final product. For this, the metal is either required to be stretched or spunk in all directions or may need a combination of both.

NIBBLING:

It is a process of continuous cutting along a contour, which may be a straight line or an irregular profile. The machines used int his operations are known as nibblers, which are portable type shearing machines.

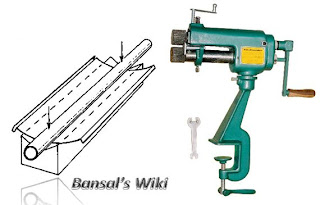

CIRCLE CUTTING:

It is the operation of circular cutting blanks or curved contours with the help of a circle cutting machine. It is also a continuous cutting operation.

PIERCING AND BLANKING:

Piercing is basically a hole punching operation while blanking is an operation of cutting out a blank. In both the cases blanks will be produced, but in the former case obtaining a blank is not the objective. It is the hole of a desired size which is the objective and the blank produced may not be used further. In the latter operation the production of a blank of the desired size is the main objective, which is a useful part for further processing.

EDGE FORMING AND WIRING:

The edges of sheet metal products are formed to ensure safety of hands while handling these products and to avoid stiffness to the products in order that they will retain their shape during handling i.e. will not get buckled or compressed by simple hand or finger pressure during handling.

JOINT MAKING:

Several means are used for joining sheet metal parts together or securing them to other metallic or non-metallic bodies. In case of very large size parts, especially when they are to be fastened to other metallic or large non-metallic bodies, screwed fastening can be used. Sheet metal parts can also be joined by riveting, welding, brazing and adhesives. Self tapping screws are more popular screwed fasteners in sheet metal work. However, still the most commonly used methods are joining the sheet metal parts by means of folded joints or self securing joints, followed by soldering and adhesive joining.

BENDING:

Sheet metal is required to be bent at different angles to shape it into the required form. The bending operation involves stretching of metal on the other surface an comprising it on the inner surface along a neutral line, which remains unchanged in length. Sheet metal can be bent by hammering over a base by hand or by means of bending or rolling machines.

DRAWING:

Thin walled hollow shapes are produced in sheet metal through the drawing operation. The operation is carried out with the help of die and punch on a suitable press. If the drawn length of the component is less than its width or diameter it is called box drawing or shallow drawing. When the drawn length is more than the width, the operation is known as deep drawing.

SAFETY WHILE WORKING IN SHEET METAL SHOP

a. Since in sheet metal work we use sharp tools and sharp cutting edges and precise hammer work is also involved so very skilled labor is used.b. Avoid using any tools whose edges are blunt or out of order.

c. For cutting sheets appropriate cutting tools or machines must be selected based on the thickness of the material to be cut.

d. Extra allowance must be provided in the sheets while cutting. So that the finished product is of correct size and finish.

No comments:

Post a Comment